HLSG series Mixing Granulator

Txoj cai ua haujlwm

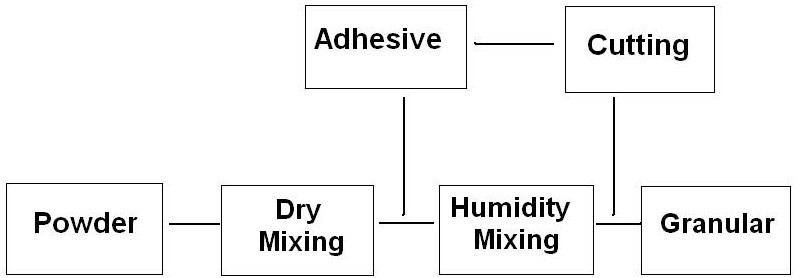

* Cov txheej txheem muaj ob txoj haujlwm suav nrog kev sib xyaw thiab granulating.

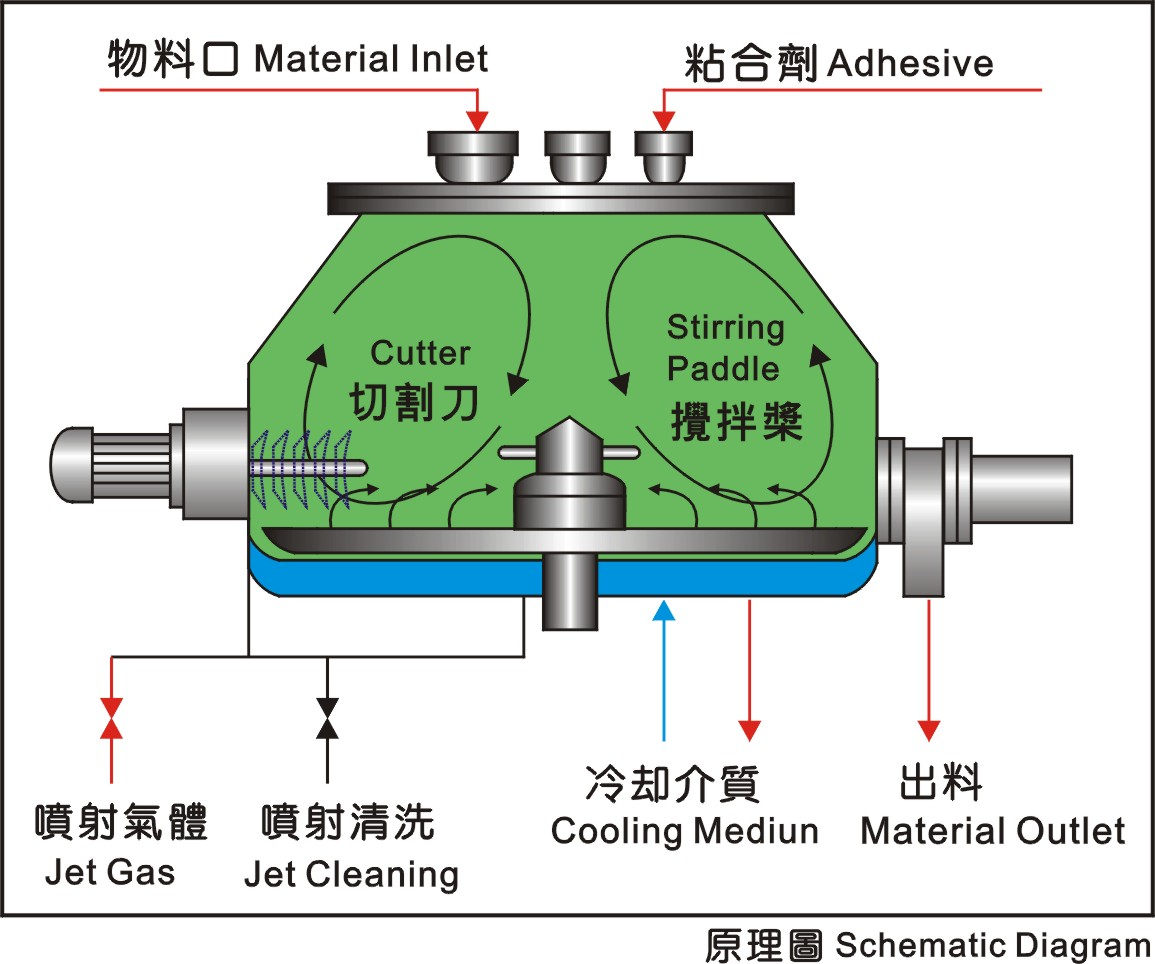

* Cov khoom siv hmoov tuaj yeem raug them rau hauv cov khoom siv yias los ntawm conical hopper thiab txuas ntxiv tig mus rau hauv lub thawv nyob rau hauv qhov kev txiav txim ntawm cov hniav sib tov thaum lub hoper raug kaw.Nyob rau hauv lub caij no, tag nrho cov ntaub ntawv loj hlob zoo li tus choj ua kua nyob rau hauv tas mus li los ntawm conical phab ntsa.Nyob rau hauv qhov kev txiav txim ntawm extrusion, kev sib txhuam raws li crumb los ntawm cov hniav thiab conical tank phab ntsa, tag nrho cov khoom yog maj mam tig rau.

xoob.Thaum kawg thaum qhib lub qhov hluav taws xob hopper, cov dej ntws tawm tau raug thawb tawm hauv qab cov teebmeem centrifugal.

* Cov khoom mos no yog tsim los tsis yog nyob ntawm kev quab yuam extrusion, ntau dua, feem ntau cov khoom me me no yog tsim tom qab txiav txuas ntxiv hauv lub xeev me me.Nyob rau hauv tag nrho, lub tshuab no tuaj yeem paub qhov kev hloov pauv ntawm cov khoom sib txawv.

Cov cim

● Nrog cov txheej txheem kev siv tshuab zoo ib yam (tus txiv neej-tshuab interface yog xaiv xaiv), lub tshuab tuaj yeem tau txais kev ruaj ntseg hauv kev ua haujlwm zoo, nrog rau kev siv phau ntawv yooj yim rau kev yooj yim ntawm kev siv tshuab thiab kev nce qib.

● Txais kev hloov kho zaus kom tswj tau lub tshuab nplawm thiab lub tshuab txiav, yooj yim los tswj qhov loj ntawm cov khoom.

● Nrog lub rotating ncej hermetically ntim nrog huab cua, nws tuaj yeem tiv thaiv tag nrho cov plua plav los ntawm kev cog lus.

● Nrog cov qauv ntawm conical hopper tank, tag nrho cov khoom siv tuaj yeem sib hloov.Lub tank yog nteg nrog ib tug interlayer nyob rau hauv qab, nyob rau hauv uas dej txias ncig system featuring ntau dua thermostatic kev ua tau zoo tshaj li cua txias system yog rooj tog, uas ua rau txhim kho qhov zoo ntawm cov khoom.

● Nrog tsis siv neeg nqa ntawm lub lauj kaub npog, lub tank qhov hluav taws xob sib piv nrog cov cuab yeej ziab khaub ncaws, nws tus kheej-tsim arm-ladder, nws yooj yim rau kev khiav lag luam.

● Lub tshuab nqa nrog lub kiv cua muaj txiaj ntsig zoo dua los ntxuav cov paddles thiab lub lauj kaub lub cev.

● Lub qhov ncauj ntawm cov khoom siv hluav taws xob tau hloov mus rau hauv arc-puab, zam qhov chaw tuag.

Technical Parameters

| Qauv | HLSG-50 | HLG-100 | HLSG-200 | HLG-300 | |

| HopperNtim | 50L | 100 L | 200L | 300 L | |

| Siv tauUa haujlwmCapactiy: Khoom siv 0.5 g / cu.cm | 12-35 : kuvL | 25-80L | 60-160 : kuvL | 80-240L | |

| lub sijhawm ua haujlwm | Mixing: txog 2 mins Granulating: txog7-14 min/batch | ||||

| Granularity | φ0.14-φ1.5mm (12-100mesh) | ||||

| Mixing Tsav | 5.5 KW TSI6Ncej | 7.5KW TSI | 15KW 6Ncej | 22Kw 6 po | |

| Rotate Ceev ntawm Stirring Paddle Frequency Kho ceev | 30-380 NwsR/min | 30-250R / min | 30-250R / min | 20-200 R / min | |

| Granulating Tsav | 1.5KW 2 po | 3 KW 2 po | 4 KW 2 po | 7.5KW TSI | |

| Rotate Ceev ntawm Granulating Paddle Frequency Kho ceev | 50-3000R / min | ||||

| Cua Compress | 0.3 stere / min 0.7Mpa (nrog rau tus neeg siv.) | ||||

| Kev sib koom ua ke ntawm Cov Dej Txias Dej | Φ10mm | ||||

| Kev sib koom ua ke ntawm Cua Compress | φ10mm | ||||

| Qhov siab ntawm Charger Outlet | 796 ibmm | 7 96mm | 9 20mm | 985mm | |

| Zuag qhia tag nrho Dimensions (L ×W× H)mm | 1935 × 662 × 1575 hli | 2078 ua702 × 1720 | 2180×810 × 2100 hli | 2420x970x2 ua450 | |

| Qhov hnyav | 400kg | 700kg ib | 1100kg ua | 1350kg ib | |